Too often, injection mold tooling is treated as a one-time expense, something to buy, install, and hope it lasts. For OEMs running multi-year programs, however, this mindset creates hidden risks. Tooling directly affects part quality, production uptime, and total cost of ownership over the life of a program. Poorly designed or managed tools lead to inconsistent parts, unplanned downtime, and higher long-term costs, even if the initial purchase seemed reasonable.

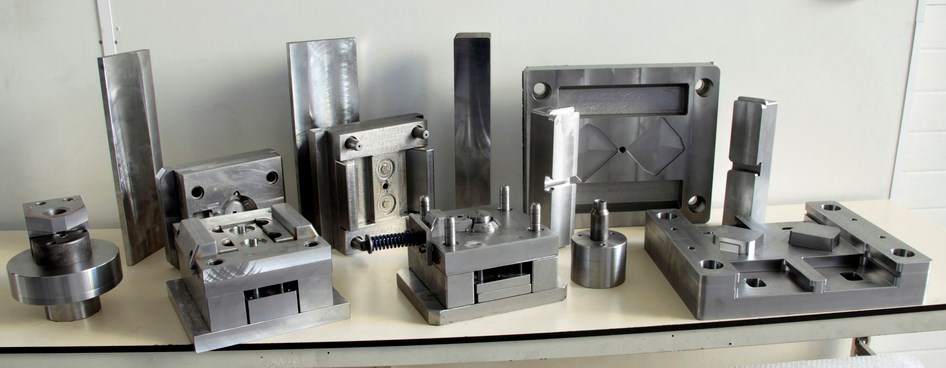

At Thogus, we approach tooling as a strategic element of every injection molding program. From design through maintenance and eventual refurbishment, our injection mold tooling services ensure parts meet specifications consistently, production stays on schedule, and programs remain cost-effective.

How Tooling Design Dictates Long-Term Part Quality

Every detail in tooling design, from gate placement to cooling channel layout to material flow, directly affects part repeatability and durability. Neglecting these elements can cause recurring defects, dimensional drift, or slower cycle times that quietly erode program efficiency.

That’s why tooling isn’t a “set it and forget it” component; it’s a precision asset. At Thogus, we treat each tool as central to sustaining quality at scale, ensuring parts consistently meet specifications across long production runs. In other words: good tooling today protects part performance tomorrow.

Why Tooling Must Be Built for the Program, Not Just the First Run

It might be tempting to optimize tooling for a quick first article, but short-term choices often create long-term problems. Underspecified steel grades, insufficient planning for multiple cavity expansion, and material-specific wear are common pitfalls that drive costly downtime later.

Thogus approaches every tool with the full program lifecycle in mind, designing and specifying for durability, flexibility, and scale from the start.

Ongoing Tooling Maintenance and Support Are Critical

High-volume programs demand proactive, disciplined maintenance to prevent costly interruptions. OEMs should know exactly who manages preventative maintenance, how quickly issues are addressed, and what monitoring systems are in place.

At Thogus, we provide in-house tooling support with documented maintenance schedules and mold performance tracking, minimizing unexpected downtime and keeping programs on track. Consistent attention to tooling protects both quality and uptime.

Partnering Early Unlocks Better Tooling Outcomes

Early collaboration between engineers and molders enables smarter tooling decisions. Input on DFM, mold flow simulations, and future demand planning ensures tools meet part, process, and performance requirements from the outset.

Thogus integrates our engineering team early in the program to align tooling with production needs, avoiding rework and inefficiencies later. Getting the tool right from day one simplifies every step that follows.

What to Look for in a Tooling Partner

When evaluating a tooling partner, OEMs should focus on technical depth, experience with multi-cavity and family tools, and the ability to manage both domestic and international tool builds. Lifecycle support — ensuring tools remain precise and reliable over years of production — is equally critical. Thogus brings deep tooling expertise, comprehensive domestic and global mold management, and a long-term planning approach that keeps programs on schedule and parts within spec. The right tooling partner safeguards quality and scales with your program.

Get the Tooling Support You Need With Thogus

Tooling can make or break a program. When designed, maintained, and managed strategically, it becomes one of your most powerful levers for quality, efficiency, and long-term cost control. Choosing a partner who treats tooling as a strategic asset — not just a one-time purchase — helps ensure your parts stay consistent and your production stays on schedule. Thogus provides full lifecycle tooling support, from early design guidance to in-house maintenance and global tool management, so your programs run smoothly at scale.

Need a partner who treats tooling as strategically as you do? Let’s talk about your next program.

Experience the Thogus Difference

Connect with us today to discuss your project and to learn more about our capabilities.